Frequently Asked Questions

What does warehouse management involve?

Managing operations within warehouses involves overseeing the receiving, storage, picking, and shipping of goods. Effective warehouse management maximizes space, improves accuracy, and streamlines workflows, making warehousing a vital component of the logistics process. A well-run warehouse strengthens the entire supply chain by ensuring timely deliveries, better stock management, and cost reduction.

How does organization and layout improve warehouse efficiency?

A thoughtfully organized warehouse layout boosts efficiency and productivity. The system allows you to customize layouts for different stages, such as:

- Separate Zoning: Allocating zones for receiving, storing, and shipping goods helps clarify operations and reduces errors.

- Logical Flow: Arranging areas so that goods move logically—from receiving to storage, then shipping—minimizes unnecessary transport within the warehouse.

- Accessibility: Frequently picked items are positioned for quick access, supported by clear labelling and signage.

What are the key strategies for effective inventory management?

Proper inventory control reduces expenses and ensures products are available when needed. Common strategies include:

- ABC Analysis: Classifying inventory into three categories by value and turnover, with focus on “A” items for greatest impact.

- Just-In-Time (JIT): Coordinating inventory orders with demand to cut storage costs and ensure availability.

- Barcode and RFID: Tracking through barcodes or RFID tags increases precision and reduces errors.

- FIFO and LIFO: Using First-In, First-Out for perishables to prevent spoilage, while Last-In, First-Out suits non-perishables.

- Vertical Storage: Racking and shelving maximize vertical space, especially in limited floor areas.

- Bin Locations: Clearly marked bin locations make it easier and faster for staff to retrieve items.

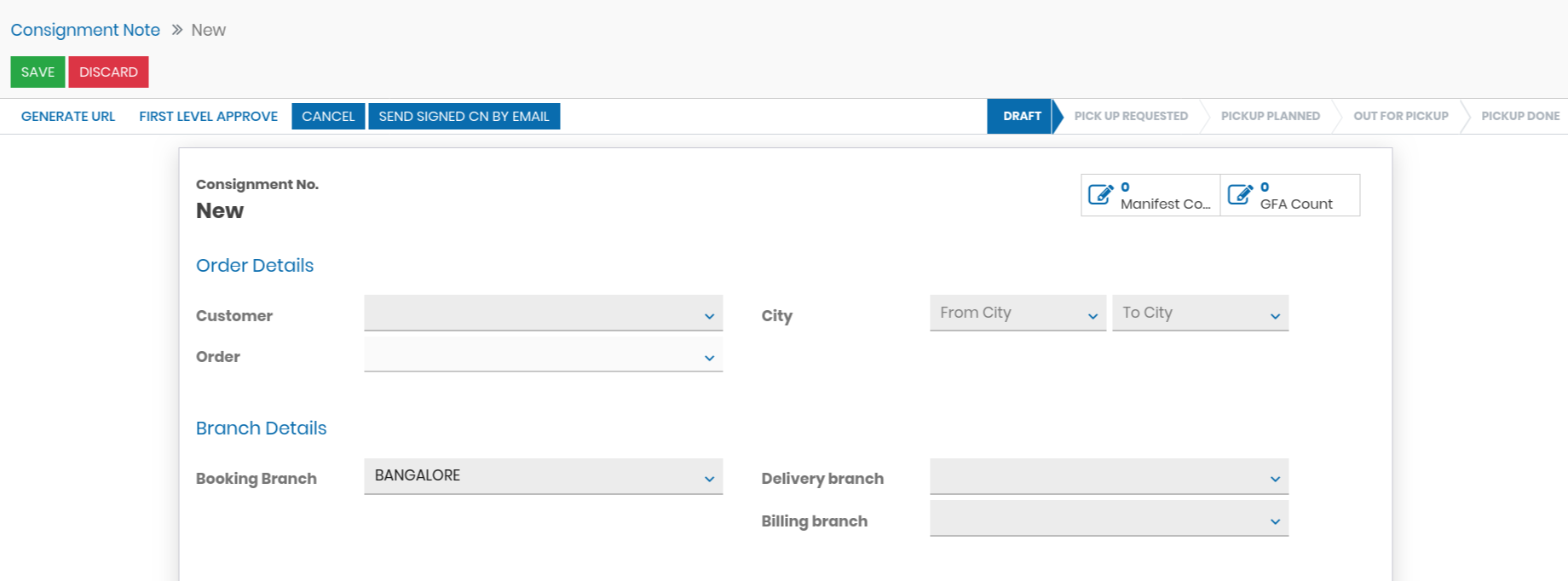

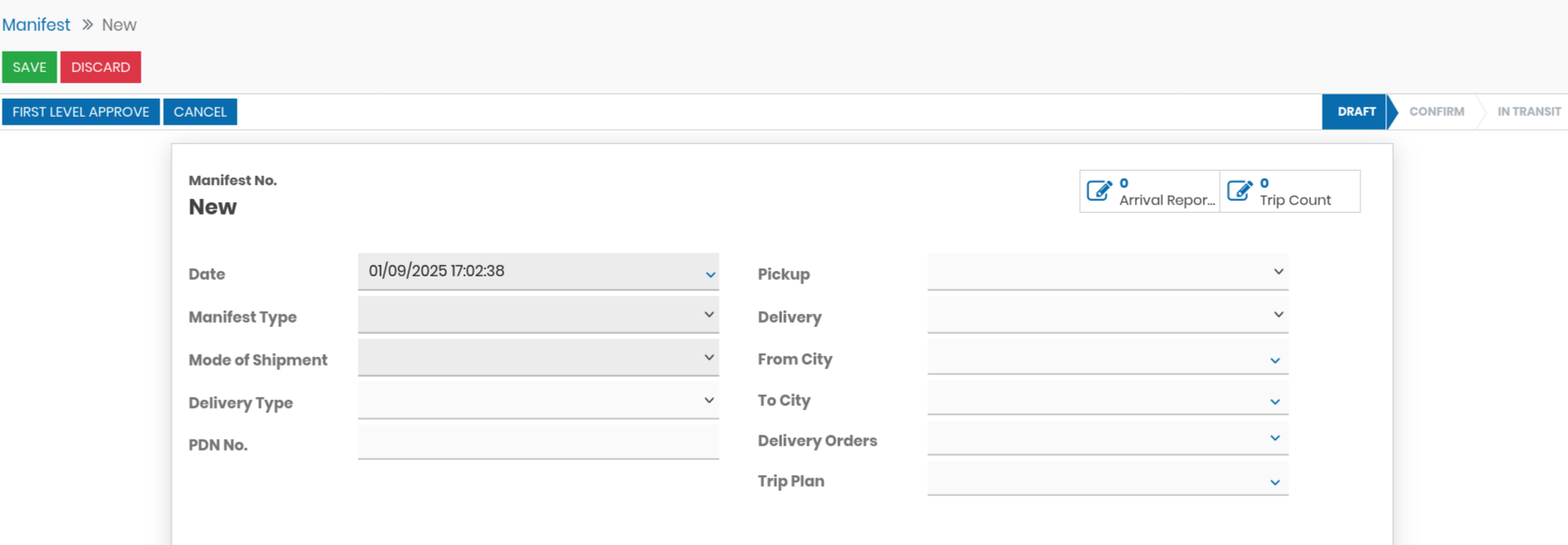

How can the receiving and pick-up process be streamlined?

A streamlined order fulfilment process is crucial for meeting customer expectations. Strategies include:

- ERP Integration: Integrating the Warehouse Management System (WMS) with Enterprise Resource Planning (ERP) systems for a comprehensive view of inventory and supply chain activities.

- Cross-Department Collaboration: Sharing data between sales, marketing, and warehouse teams to ensure efficiency and alignment of goals.

- Trend Analysis: Leveraging data and analytics to identify problems, reveal patterns, and support continual improvement in inventory and staffing decisions.

Why are good warehousing practices important?

Merely having a warehouse is not enough for maximum efficiency. Implementing good warehousing practices reduces inefficiencies, lowers costs, and helps overcome logistical hurdles. Without such practices, businesses struggle to meet customer demands. Effective warehouse management is essential for maintaining a competitive advantage and ensuring supply chain success.